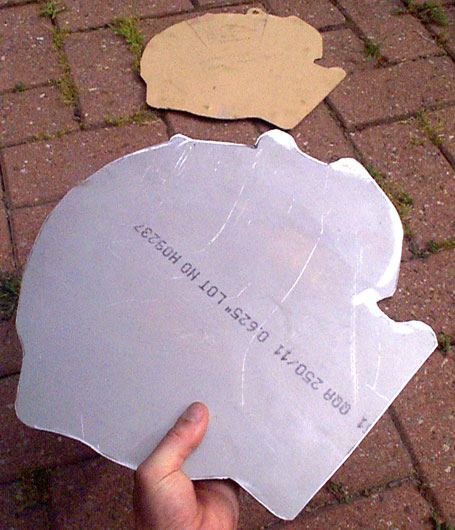

Cardboard template, then 5/8th aluminum sheet

| < prev. photo | next photo > |

Making the template for the adapter was pretty easy: a piece of cardboard (top) was taped across the bell housing, the outline of which was then traced on it. The cardboard cutout then served as a template for the aluminum plate, cut on a bandsaw. (A jigsaw or even a hacksaw will work, since aluminum is a fairly soft metal.)

It's not even strictly necessary to perfectly follow the bellhousing outline when making the plate - some people use a simple rectangle. That will work (with bolt holes in the right spots, obviously) provided the edges/corners of the plate don't interfere with other components in the motor bay.

The "traced" shape of the adapter looks nicer though, and ensures there won't be any clearance issues.

It's not even strictly necessary to perfectly follow the bellhousing outline when making the plate - some people use a simple rectangle. That will work (with bolt holes in the right spots, obviously) provided the edges/corners of the plate don't interfere with other components in the motor bay.

The "traced" shape of the adapter looks nicer though, and ensures there won't be any clearance issues.

View all ForkenSwift galleries > Adapter plate ...

Cardboard template, then 5/8th aluminum sheet

Cardboard template, then 5/8th aluminum sheetMaking the template for the adapter was pretty easy: a piece of cardboard (top) was taped across the bell housing, the o... |

But first check that the motor diameter will fit the transmission!

But first check that the motor diameter will fit the transmission!When planning the adapter plate, we discovered that the the forklift's main 12.5 inch diameter traction motor that we ha... |

Adapter plate on transmission

Adapter plate on transmissionOne of the most critical jobs involving the plate is aligning the electric motor perfectly with the transmission input s... |

Metro adapter plate dimensions

Metro adapter plate dimensionsFor anyone else looking for rough dimensions of the bell housing, here are 2 dimensions taken from the adapter plate.... |

Metro adapter plate dimensions

Metro adapter plate dimensionsFor anyone else looking for rough dimensions of the bell housing, here are 2 dimensions taken from the adapter plate.... |